| Railway Cables | ||||||

|

||||||

NR/L2/SIG/30060 Axle Counter Cable

NR/L2/SIG/30060 Axle Counter Cable

Application

Axle Counter cable is used to connect the various elements of the AzLM Axle Counter System. It is suitable for

installation in trackside cable troughing, buried duct route and installed in open air on the ballast and clipped to

sleepers as required. Quad types XQS and XQZ are used to connect the EAK Junction box or termination to the

EAK (Mushroom) and Multi Twisted pair types XPS and XPZ are used to connect EAK to the ACE (Axle Counter

Evaluator) equipment.

Standards

NR/L2/SIG/30060

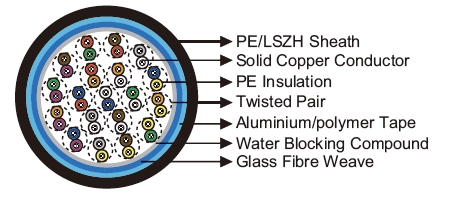

Construction

Conductors: Solid tinned copper conductor according BS EN60228:2005(previously BS6360).

Insulation: PE (Polyethylene) Type 03 to BS6234.

Water Blocking Compound:Petroleum jelly (XPS and XQS types only)

Anti-Rodent Protection: Glass fibre weave.

Moisture Barrier: Aluminium/polymer laminate tape.

Sheath: PE (Polyethylene) Type 03C to BS6234 or LSZH (Low Smoke Zero Halogen).

Electrical Characteristics at 20℃

| Nominal Conductor Diameter | mm | 0.9 | 1.4 |

|---|---|---|---|

| Nominal Conductor Cross Section | mm2 | 0.63 | 1.5 |

| Maximum Conductor Resistance | Ω/km | 30.0 | 12.5 |

| Minimum Insulation Resistance @500 V DC (1min) | MΩ.km | 5000 | 5000 |

| Nominal Mutual Capacitance @800Hz/1000Hz (AC) | nF/km | 45 | 50 |

| Dielectric Strength, conductor to screen (DC voltage 2mins) | V | 3000 | 3000 |

| Maximum Average Attenuation | |||

| @1.0KHz @2.4KHz |

dB/km dB/km | 0.73 | 0.45 |

| 1.10 | 0.62 | ||

| @40KHz | dB/km | 2.88 | 1.77 |

| @90KHz | dB/km | 3.70 | 2.41 |

| @1.024MHz | dB/km | 11.2 | 7.45 |

| Minimum Average Near-end Crosstalk Attenuation | |||

| @1.0KHz | dB/km | 60 | 60 |

| @2.4KHz | dB/km | 60 | 60 |

|---|---|---|---|

| @40KHz | dB/km | 50 | 50 |

| @90KHz | dB/km | 50 | 50 |

| @1.024MHz | dB/km | 35 | 35 |

| Maximum Reduction factor @100V/km,50Hz | |||

| EMI RF 1 (modest level) | 0.65 | 0.65 | |

| EMI RF 2 (medium level) | 0.45 | 0.45 | |

Mechanical and Thermal Properties

Minimum Bending Radius: 7.5xOD

Temperature Range: -25℃ to +85℃

Colour Identification:

Sheath Colour: Black

Core Colours

| Pair Number | A Wire | B Wire | Pair Number | A Wire | B Wire |

|---|---|---|---|---|---|

| 1 | WHITE | BLUE | 13 | YELLOW | GREEN |

| 2 | WHITE | ORANGE | 14 | YELLOW | BROWN |

| 3 | WHITE | GREEN | 15 | YELLOW | GREY |

| 4 | WHITE | BROWN | 16 | VIOLET | BLUE |

| 5 | WHITE | GREY | 17 | VIOLET | ORANGE |

| 6 | RED | BLUE | 18 | VIOLET | GREEN |

| 7 | RED | ORANGE | 19 | VIOLET | BROWN |

| 8 | RED | GREEN | 20 | VIOLET | GREY |

| 9 | RED | BROWN | 21 | TURQUOISE | BLUE |

| 10 | RED | GREY | 22 | TURQUOISE | ORANGE |

| 11 | YELLOW | BLUE | 23 | TURQUOISE | GREEN |

| 12 | YELLOW | ORANGE | 24 | TURQUOISE | BROWN |

Dimensions And Weight

Type XPS Multi-twisted-pair Cables

|

Number of Pairs Nominal Sheath Thickness (n) mm |

Maximum Overall Diameter Nominal Weight mm kg/km | ||

|---|---|---|---|

| 0.9mm conductor | |||

| 2 | 2.5 | 13.8 | 215 |

| 10 | 2.5 | 24.7 | 530 |

| 12 | 2.5 | 26.4 | 584 |

| 19 | 2.5 | 31.4 | 810 |

| 24 | 2.5 | 34.5 | 982 |

| 1.4mm conductor | |||

| 2 | 2.5 | 16.4 | 320 |

|

Number of Pairs Nominal Sheath Thickness (n) mm |

Maximum Overall Diameter Nominal Weight mm kg/km | ||

|---|---|---|---|

| 10 | 2.5 | 31.4 | 910 |

| 12 | 2.5 | 33.8 | 1016 |

| 19 | 2.5 | 40.8 | 1460 |

| 24 | 2.5 | 45.0 | 1787 |

|

Number of Pairs Nominal Sheath Thickness (n) mm |

Maximum Overall Diameter Nominal Weight mm kg/km | ||

|---|---|---|---|

| 0.9mm conductor | |||

| 2 | 2.5 | 13.8 | 200 |

| 10 | 2.5 | 24.7 | 424 |

| 12 | 2.5 | 26.4 | 468 |

| 19 | 2.5 | 31.4 | 632 |

| 24 | 2.5 | 34.5 | 746 |

| 1.4mm conductor | |||

| 2 | 2.5 | 16.4 | 314 |

| 10 | 2.5 | 31.4 | 807 |

| 12 | 2.5 | 33.8 | 909 |

| 19 | 2.5 | 40.8 | 1284 |

| 24 | 2.5 | 45.0 | 1548 |

| Quad x Conductor Diameter(n) | Nominal Sheath Thickness mm | Maximum Overall Diameter mm | Nominal Weight kg/km |

|---|---|---|---|

| 1×0.9 | 2.5 | 11.8 | 140 |

| 1×1.4 | 2.5 | 13.8 | 221 |

| Quad x Conductor Diameter(n) | Nominal Sheath Thickness mm | Maximum Overall Diameter mm | Nominal Weight kg/km |

|---|---|---|---|

| 1×0.9 | 2.5 | 11.8 | 172 |

| 1×1.4 | 2.5 | 13.8 | 226 |